- Navigator

- Industry Analytics and Strategy

- Prospecting and Business Attraction

- Manufacturing

Key Takeaways

Key Takeaways

This section was generated by AI and then edited by staff. The rest of the article is not AI-generated.

- Driven by trade policy uncertainty, supply chain disruptions, and national security concerns, companies are increasingly choosing to manufacture within the US rather than rely on global production.

- Sectors like semiconductors, industrial equipment, medical devices, and automotive are driving reshoring and FDI, with semiconductor projects alone accounting for two-thirds of foreign capital investment between late 2024 and early 2025.

- Access to reliable, scalable, and renewable energy—along with workforce availability—is now a top factor in site selection, elevating regions like Phoenix, Dallas-Fort Worth, and Salt Lake City.

- Strategic, measured approaches are essential. While momentum is strong, companies must plan for long-term success by investing in workforce development, navigating logistics challenges, and balancing domestic expansion with global relationships.

In today’s rapidly shifting global landscape, reshoring and foreign direct investment (FDI) have emerged as strategically and economically significant trends for US manufacturers.

While the term “reshoring” has become a fixture in both political and cultural conversations, understanding the realities of what is happening on the ground and what is driving decision makers helps put long-term potential into perspective.

This article explores the current state of reshoring and FDI, quantifying the scale of activity, identifying the industries driving these movements, and highlighting the factors motivating companies to bring operations back to the US or expand domestically. Drawing on real-time insights and the latest market data, this article highlights reshoring and FDI trends and offers actionable guidance for firms considering these strategies.

Market Drivers

While traditional reshoring often refers to US-based companies bringing manufacturing back home after locating facilities internationally, this article also accounts for FDI and how those investments are impacting business prospects for the manufacturing industry.

A growing number of global manufacturers are adopting a “local-for-local” strategy by building facilities inside the US to serve the US market. This approach reflects a growing consensus: to sell into the US market, it’s increasingly necessary to manufacture within it.

This operational shift reduces global trade exposure, increases proximity to key customers, and fulfills many of the same strategic objectives as domestic reshoring: resilience, responsiveness, and reduced geopolitical risk. It is driven by several overlapping factors that are constantly evolving:

- Shipping cost and supply chain reliability: Ocean freight volatility, port congestion, and geopolitical uncertainty are causing firms to prioritize proximity and predictability over low-cost labor.

- Customer pressure and service responsiveness: For suppliers serving American original equipment manufacturers (OEMs), especially in auto, aerospace, and electronics, reshoring offers greater agility, just-in-time capabilities, and credibility with US buyers.

- Tariff mitigation and policy risk: Firms are explicitly citing the desire to avoid potential future tariffs. This includes Korean and Taiwanese electronics manufacturers who have experienced whiplash from shifting US-China trade policy.

- National security risks: From valuable electronic components to US intellectual property, there has been a renewed call to return sensitive materials and production to the US to secure intelligence and supply chains.

Reshoring and FDI: By the Numbers

In 2024, US manufacturers and foreign investors announced 244,000 reshoring and FDI-related jobs. This was a slight decline from the record-setting 268,000 jobs in 2023, but still the second-highest year on record. These announcements contribute to a cumulative total of more than 2.5 million jobs reshored or created through FDI since 2010.

Foreign Direct Investment Snapshot

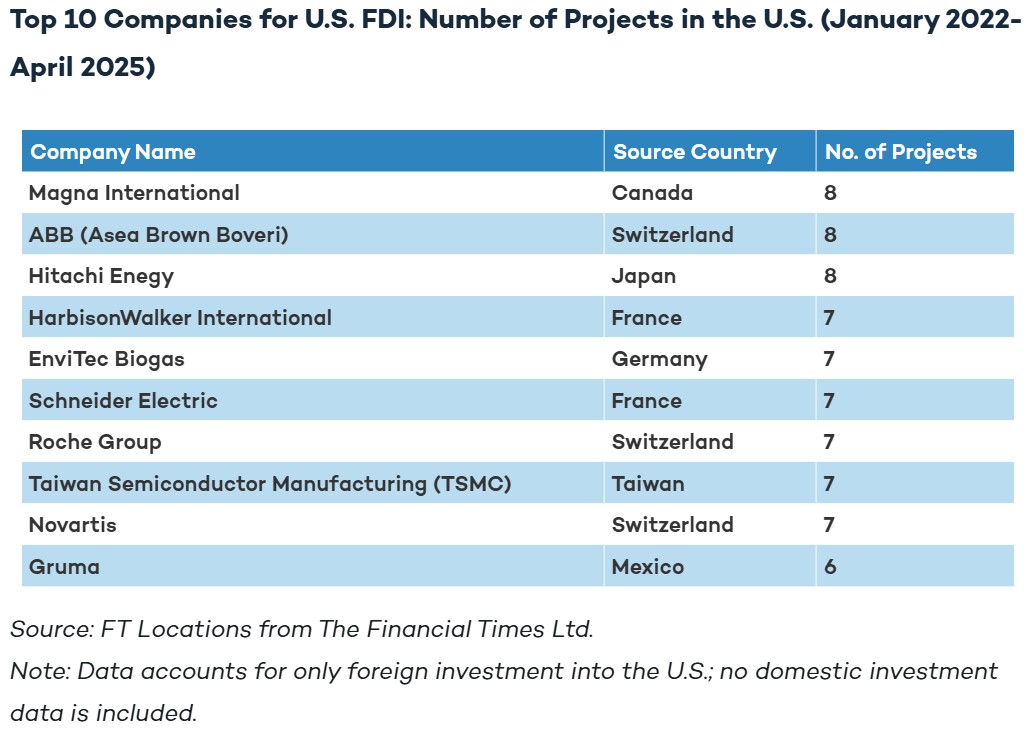

A snapshot of FDI in the US over the last three years shows which countries are driving the activity from abroad and what types of industries tend to generate the largest capital investments. Let’s look at two key indicators for FDI.

What companies had the highest number of projects in the US over the last three years?

Individual companies from Canada, Switzerland, and Japan each had eight projects in the US between January 2022 and April 2025.

The top 10 companies in the table accounted for about 5% of all projects between January 2022 and April 2025.

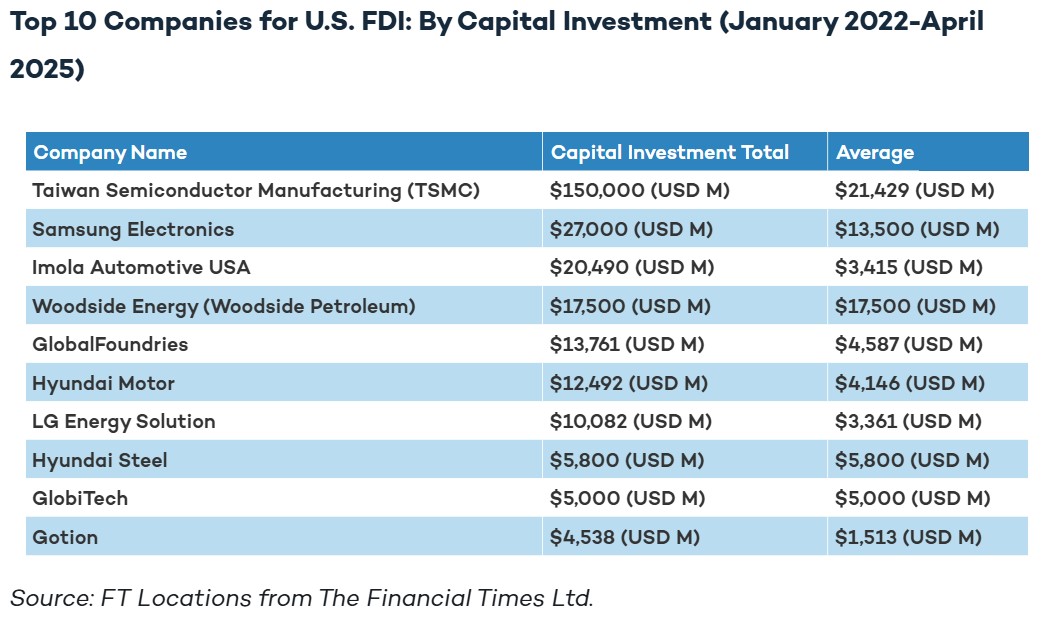

What companies made the greatest capital investment in the US over the last three years?

Taiwan Semiconductor (TSMC) invested about $150 billion in the US over the past three years, approximately five and a half times more capital than Samsung Electronics, which had the second highest investment amount.

The top 10 companies in the table accounted for just over half of all capital investment between January 2022 and April 2025.

What Industries Are Driving this Activity?

A handful of industries and related supply chain elements are driving reshoring and FDI in the US. (Some quantitative data and company examples in this section are derived from fDi Markets data.)

Semiconductors

From October 2024 to April 2025, semiconductor projects represented only about 5% of all announcements. However, they accounted for a staggering $102.6 billion in capital investment, or approximately two-thirds of all foreign capital invested during that period. These investments created over 17,600 new jobs, largely due to mega-deals like TSMC (Taiwan), Samsung (South Korea), and ASML (Netherlands).

The CHIPS Act and global supply chain realignment in response to chip shortages are key drivers behind this trend. This sector exemplifies long-term strategic reshoring to reduce risk in high-value critical supply chains.

Industrial Equipment: Building the Backbone of US Manufacturing Resilience

The industrial equipment sector, encompassing machinery, components, and specialized systems used across manufacturing industries, has become one of the most active areas for reshoring among international firms. From German precision toolmakers to Italian robotics and furnace manufacturers, foreign companies increasingly choose to establish US-based operations to serve their North American customers more directly.

According to FDI data from The Financial Times, between January 2022 and April 2025, this sector saw almost 200 foreign investment projects, making it one of the most active in terms of project count. However, these projects tend to have smaller capital outlays compared to semiconductors or automotive investments. These projects typically involve:

- Machine shops and parts fabrication

- Robotics, automation, and CNC equipment

- Furnaces, heat treatment systems, and tooling

- Assembly and distribution facilities

Medical Devices and Biotechnology

Biotechnology and medical device manufacturing saw significant FDI activity between January 2022 and April 2025, particularly in the form of smaller, innovation-focused investments.

These projects, led by companies like Roche, Novartis, and Tradichem, were largely concentrated in research hubs with robust clinical trial infrastructure and regulatory alignment.

Automotive and Aerospace: Supplier Networks Localizing

The US automotive and aerospace manufacturing sectors have also attracted a steady stream of reshoring and expansion activity from international OEMs and Tier 1 suppliers.

Companies such as Kia Motors, Hansae Mobility, and Vulcanair have launched or expanded operations in the US to reduce lead times and be closer to final assembly lines and end users. From 2022 through early 2025, these companies leveraged US infrastructure and workforce availability, particularly in the South and Midwest.

Food and Packaging: Consumer-Driven Localization

The food processing and packaging sectors are seeing a reshoring wave primarily among European companies seeking regulatory alignment with the USDA and FDA, and to reduce transportation and spoilage costs.

Notable examples include investments by Lactalis and Schar USA, which emphasize localized production to meet American consumer preferences and regulatory expectations. These projects, often medium-sized in scope, play a critical role in strengthening US food security and regional supply chains. The broader reshoring trend in this space is also influenced by rising global logistics costs and growing demand for sustainable packaging solutions.

Where Is the Most Investment Happening in the US?

As manufacturers rethink their global footprint, they face the lofty task of identifying where their company is best suited to thrive in the US. While geopolitical factors are contributing to the acceleration of reshoring and FDI activity, the next layer of decision-making comes down to site readiness and the infrastructure to support it.

The availability of reliable and cost-effective power is now the top competitive factor for site location decisions. From semiconductors and electric vehicles (EVs) to data centers and chemicals, many of today’s biggest reshoring projects are massive energy users. In the 2024 Site Selectors Guild: State of Site Selection report, electric power capacity was ranked as the #1 most critical site selection factor for industrial projects—a shift from traditional cost-based models.

The regions’ winning projects have one thing in common: proactive utilities that can deliver on:

- Megawatt availability

- Grid access speed and transparency

- Renewable energy integration

It is worth noting that workforce/labor force availability continues to be top of mind as well in industrial projects across the US.

Locations that have been able to prove their ability to provide power, along with other attractive competitive factors, include:

Phoenix, AZ: The epicenter of US semiconductor reshoring, massive investment in chip fabrication facilities has positioned Phoenix as a leading destination for high-tech manufacturing.

Houston, Plano, Fort Worth, and Dallas, TX: Numerous communities in Texas have attracted developments in semiconductor, life sciences, and electronic component technologies.

Salt Lake City, UT: Known for clean energy and advanced materials, Salt Lake City is attracting green manufacturing and tech-related reshoring.

Memphis, TN: The city’s status as a logistics and distribution hub is drawing investment from companies looking to shorten supply chains and streamline US market access.

Duncan, SC: Located in the Upstate South Carolina region, Duncan is benefiting from strong momentum in automotive, aerospace, and EV supply chain reshoring.

Insights and Observations from the Field

Through Camoin Associates’ business intelligence and lead generation work, our staff collects real-time information from thousands of C-suite executives on their site location and investment priorities, which helps bring additional context to the data presented above.

Our team has seen a notable increase in overseas prospects, particularly from Canada, Germany, and South Korea, stating upfront that their interest in a US location is driven in part by pre-empting future trade restrictions.

- In a recent discussion we had with a Canadian advanced materials firm, executives explicitly mentioned US steel and aluminum tariffs as part of their rationale for establishing a domestic production footprint.

- Similarly, in the Southeast, two German automotive suppliers emphasized their concern over “Buy America” provisions and the need to secure long-term access to US federal contracts.

- LS Electric (South Korea) and Inventec (Taiwan) identified US tariff policy as a key reshoring driver.

- Hansae Mobility (Korea) noted it was reshoring to be near its US customer (Stellantis) to reduce exposure to shifting US tariffs.

While the recent surge in reshoring and FDI in US manufacturing signals a promising shift, it is critical to view these trends with measured optimism. Much of this movement is driven by trade policy uncertainty and the imperative for more resilient supply chains, rather than purely by cost advantages or customer preference.

Advances in automation and other advanced manufacturing technologies have made reshoring more viable and sustainable, yet significant risks remain. Geopolitical tensions, shifting trade dynamics, and deeply entrenched global supply chains all present potential headwinds that could slow or even reverse current momentum.

For businesses considering reshoring or new investment, success will hinge on proactive strategies related to:

- Identifying and developing critical workforce skills in partnership with local education and training providers

- Gaining a deep understanding of new markets and customer bases

- Navigating complex transportation and logistics networks

In the end, it is critical that businesses and industries, along with the economic developers who support them, avoid “all or nothing” approaches and instead take an “and/both” approach to growing manufacturing domestically while maintaining connections and advancing opportunities globally.

This article was originally published on the Manufacturers Alliance website on July 16, 2025.

About the Authors

Alexandra Tranmer, CEcD, is the Director of Industry and Workforce at Camoin Associates. She has an Honors Bachelor of Arts degree and a Master of Science degree in Planning (MScPl) from the University of Toronto in Ontario, Canada. As a senior project manager, Alex has led complex strategic planning efforts in geographies ranging from bustling urban centers to pastoral tourist destinations, requiring adept stakeholder management and collaboration. She works with clients to balance the competing interests of stakeholders while ultimately helping them develop an ambitious yet achievable plan under their current organizational climate.

Dillion Roberts is the Director of ProspectEngage™ at Camoin Associates. He has a Bachelor of Science degree in Technology Systems with an emphasis in Technical Management from from Utah State University and a minor in Business Management and Leadership through the Huntsman School of Business. With over 16 years of versatile expertise in project management, sales, marketing, and client account stewardship, Dillion is a seasoned professional adept at fostering economic development and driving transformative change. Drawing upon his extensive industry experience, he goes beyond the conventional, spearheading business attraction initiatives that fuel growth and innovation.

📍 Related Articles:

![US Foreign Direct Investment (FDI) 2025 Mid-Year Trends [Infographic]](jpg/web-header-900x600.jpg)